Every Type of Plastic Used By LEGO

/Today’s guest article comes from Rylie Howerter, one of the LEGO fan community’s foremost color and materials enthusiasts. Their color guide is one of our go-to LEGO references here at BrickNerd, and you can follow them on Flickr, Instagram and Patreon.

A Plethora of Plastics

Most people know that most LEGO bricks are made of ABS, but that’s not the only plastic that LEGO uses! Historically and currently, LEGO bricks are made with a variety of materials depending on the use case. This article will explore many of them, with a brief overview of their properties and when/how they have been used.

Disclaimer: I am only a LEGO enthusiast, not a plastics specialist by any means. If anything here seems wrong or misleading, please do let me know and I will gladly correct it! Also note that within each plastic category, there is the potential for additives and colorants that may further affect how the part performs. Most of the plastics below are really names for families of hundreds of subtly different plastics. LEGO’s exact plastic formulations are trade secrets, and for good reason.

Much of this article was informed by The LEGO Group’s own materials webpage as well as hobbyist researchers such as Gary Istok, Bailey Fullarton, and others. All images are my own unless noted otherwise.

CA (Cellulose Acetate)

CA is a moderately hard thermoplastic (a plastic that softens when heated and hardens when cooled). It can have very glossy, vibrant coloration, and good transparency, but it doesn’t hold its color over time as well as other plastics. The very first LEGO bricks in 1949 were made from CA, and this use continued through the Town Plan and Samsonite eras. However, over time CA has a tendency to warp, often severely. Many of these bricks are now incompatible with modern bricks due to this deformation. LEGO switched to ABS around 1963, and fully phased CA out by 1970.

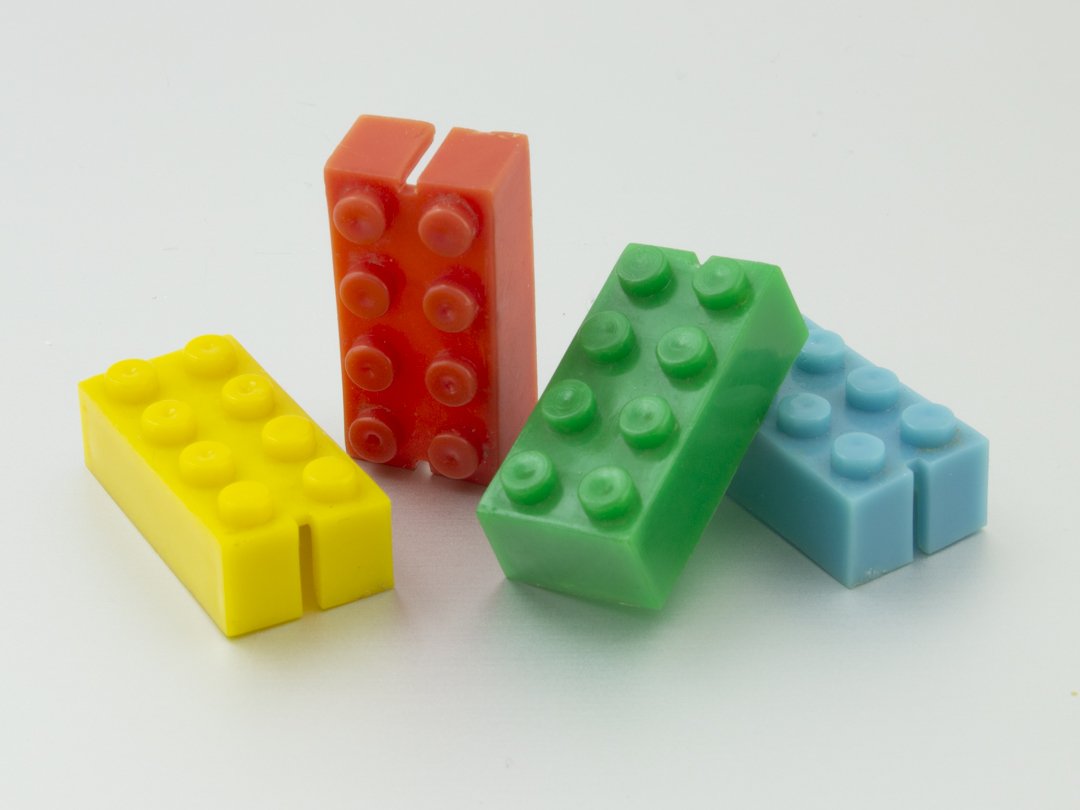

HIPS (High Impact Polystyrene)

Polystyrene is a very durable plastic, used for some early bricks (PRIMA, waffle plates) and modern baseplates. Despite its impact resistance, it can be brittle, and has a tendency to turn white along the edges as it wears (see the factory-cut edge of the baseplate pictured, and play-worn Minitalia bricks). Older polystyrene bricks have a very high-pitched, glassy sound when dropped. I believe LEGO now adds a rubber additive to HIPS to increase its strength and flexibility, as well as decrease the whitening effect.

Bakelite (Polyoxybenzylmethylenglycolanhydride)*

Bakelite is a trademarked name and the world’s first synthetic plastic. Unlike thermoplastics like CA and ABS, Bakelite is a thermoset, meaning that once the resin has hardened it cannot be remolded. It is heat-resistant and inflexible, as well as very shiny and slightly translucent. These bricks were produced for LEGO by the Swedish company Geas Konstharts from 1950–1953, before they rebranded as PRIMA and switched to a polystyrene, which was likely cheaper to produce and had more coloration potential.

*At least, this is the current AFOL historian consensus for these Geas bricks. From my limited readings, it seems they may more likely be Catalin or Beetle, given the consistent bright colors and slight translucency.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a strong, stable, scratch-resistant thermoplastic, and makes up the vast majority of LEGO pieces since 1963. It is a translucent-milky color when uncolored, so it cannot be used for transparent parts. LEGO used to receive their raw ABS granules from Bayer, which has a long history of testing 2x4 bricks for LEGO in unusual colors and molds. In 2004 Bayer’s ABS division became Lanxess, which now provides LEGO with ABS under the brand name Novodur (colored with Lanxess’s Macrolex dyes).

SAN (Styrene-Acrylonitrile Resin)

SAN is a very clear, glassy plastic often used for inexpensive drinkware. It is rigid and strong, but can turn yellow over time. Its clarity makes it great for prisms, and I believe LEGO also used it for windscreens from the 70 to early 90s.

PP (Polypropylene)

Polypropylene is a tough, flexible plastic, used for most Bionicle weapons and minifigure parts that might break easily if they were a more rigid plastic. The plastic’s flexibility allows for it to be used as a “living hinge”, as in the book pictured here. Because it cannot be fully transparent, colors like 48 Transparent Green (pictured) look nearly opaque in PP, sometimes being mistaken for their solid counterpart color. PP often turns whitish along the edges as it wears. It is used for as varied applications as large buckets and pick-a-brick cups, and even the polybags that parts and small sets come in!

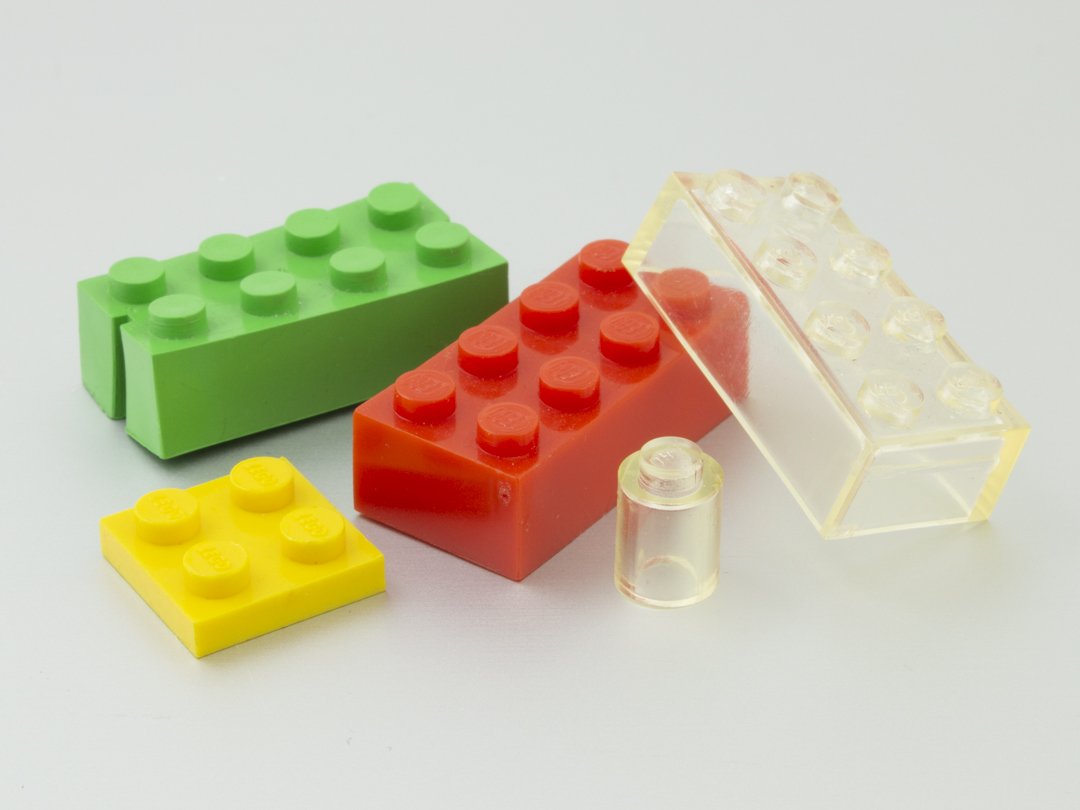

PC (Polycarbonate)

Polycarbonate is a strong material that can be very clear. I believe that PC replaced CA for transparent parts at the same time that ABS replaced CA for opaque parts in 1963. The vast majority of transparent parts in LEGO’s history are made of PC — but around 2019, LEGO switched to MABS, so PC is now only used for opaque parts like hinges and joints. Transparent PC tends to bond to itself when connected tightly, which is why it’s so difficult to remove a transparent cone from a 4L bar, and PC minifigures only exist as rare delicate prototypes. The PC LEGO uses is Lanxess’s Makrolon.

MABS (Methyl Methacrylate-Acrylonitrile-Butadiene-Styrene)

This thermoplastic offers high strength and impact resistance, though not quite as strong as standard ABS. But unlike ABS, MABS offers high transparency and can display very bright transparent colors and glitter effects. Since around 2018, LEGO has switched to using MABS for most transparent parts (possibly because PC uses BPA, which is increasingly regulated by the EU—read more about the transition in this BrickNerd article). It tends to look slightly milkier than older transparent parts, but I believe this is improving as LEGO continues to refine the material.

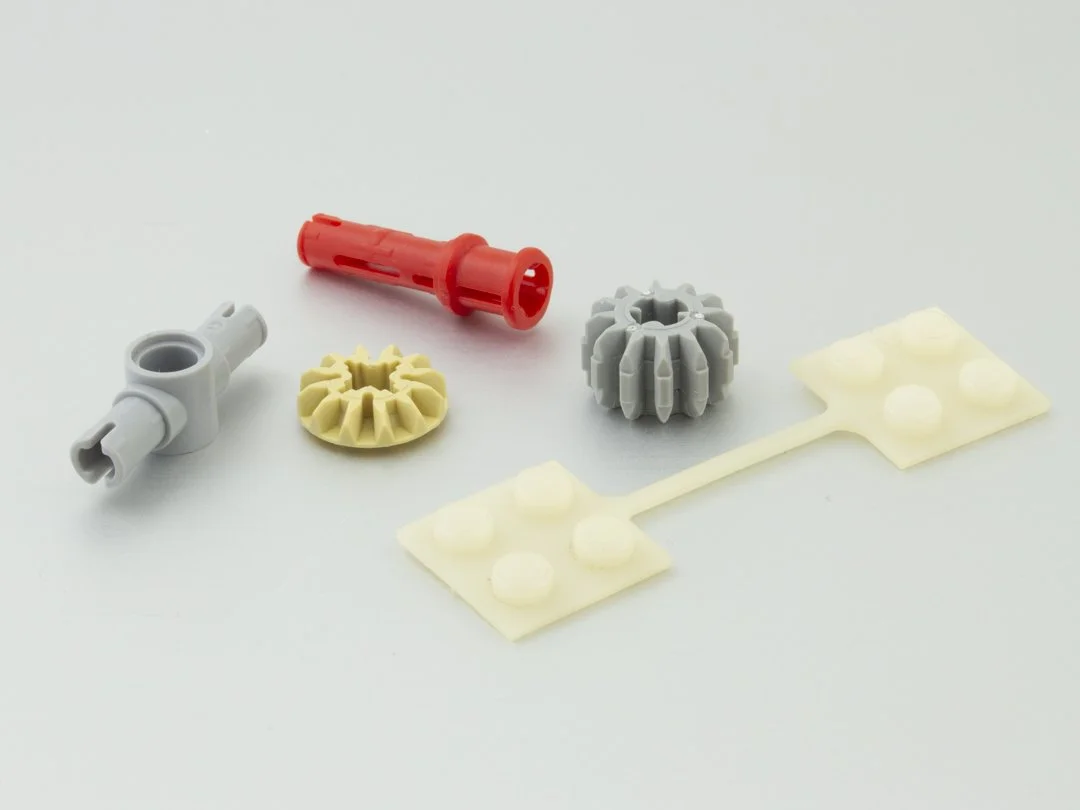

PA (Polyamide)

Polyamide, or nylon, is a very strong plastic that holds up against high impact, lending itself to connectors and gears, even in non-LEGO machinery, where durability is more important than perfect coloration. LEGO used nylon as far back as the 1960s for flexible vehicle couplings (pictured right), although today most of these have hardened and are very brittle. Modern Technic bricks with pins, such as 42929, are dual-molded so the brick part is ABS and the pin is PA (this is why they show up in BrickSet as “multicombination”, even though it’s the same color throughout).

POM (Polyoxymethylene)

Also known as acetal, POM offers high stability and low friction, like PA. POM is more pliable, making it suitable for long axles that need to be able to flex a little without breaking.

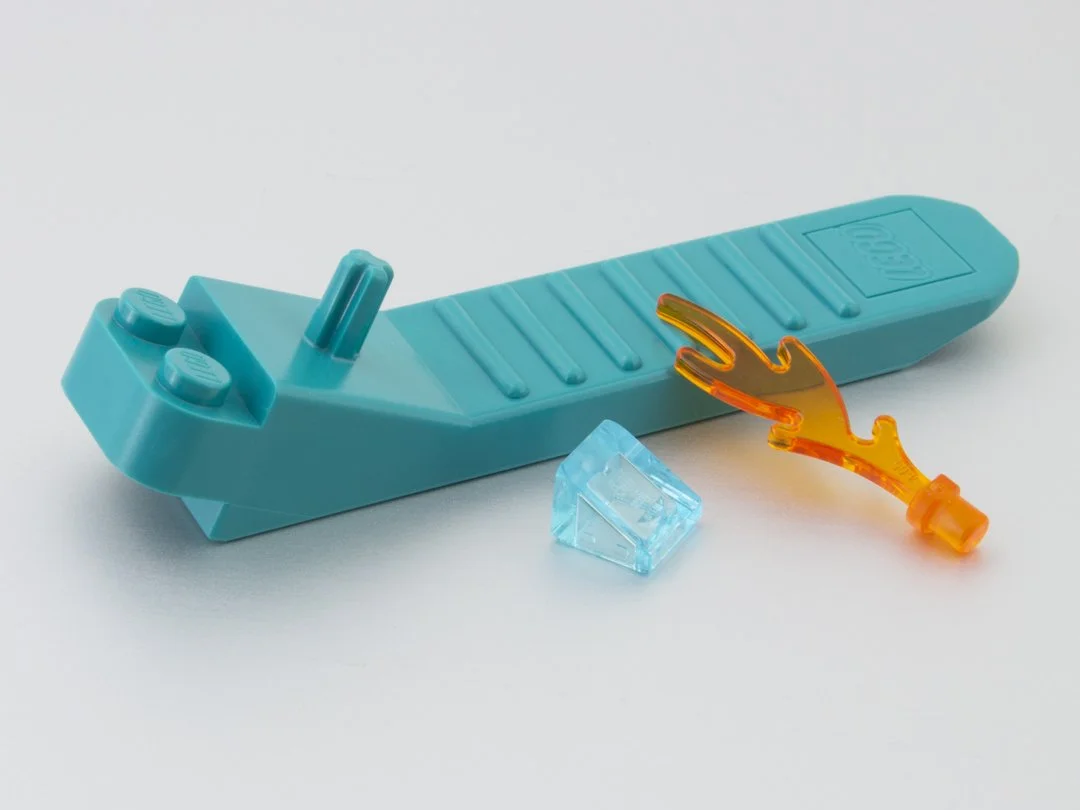

TP (Thermoplastic Polyester)

TP is a broad category of materials, including PET, that are strong and can be very transparent. In LEGO, it is both tougher than PC (so the thin fire doesn’t snap) and softer than ABS (so the brick separator is less likely to damage other bricks). Fun fact, older separators were made out of HV-PC instead, so you might have both varieties in your collection.

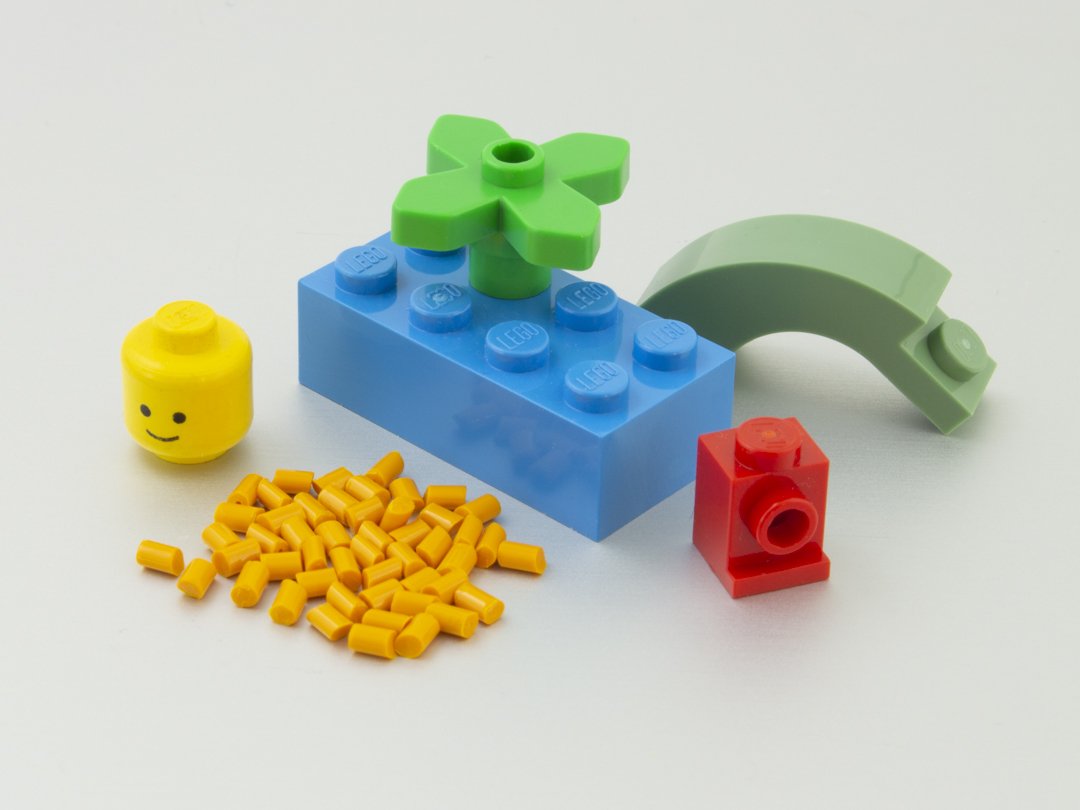

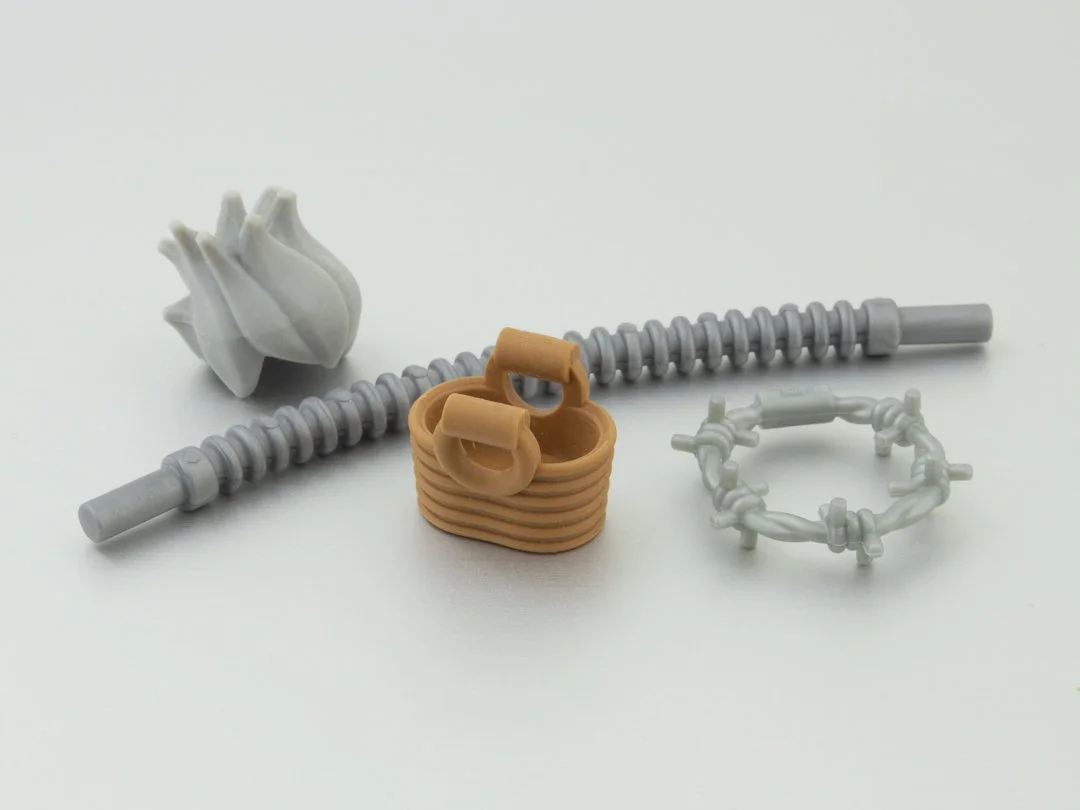

PE (Polyethylene)

Polyethylene is a very common thermoplastic with low strength and rigidity, and a low melting point. Its relative flexibility makes it perfect for large thin parts like leaves and stems. On the left in the photo above are high-density polyethylene (HDPE), while the right two parts are low-density polyethylene (LDPE): the lower the density, the softer it is. PE is a very versatile plastic — the thin plastic in LEGO store shopping bags is LDPE, and some carry cases that have a living hinge are HDPE. In 2018, LEGO started sourcing their PE from 98% sugarcane (the two small leaves pictured), as part of their long-term sustainability plan. Although the source is different, the end product is, in theory, identical.

MTPO (Metallocene Thermoplastic Polyolefin)

MTPO is a very soft material that LEGO uses for parts that need to bend sharply without being damaged. I wasn’t able to find much information on this material, but it seems it’s a variant of TPO, a category of thermoplastics blended with elastomers.

TPU (Thermoplastic Polyurethane)

TPU is a very strong but elastic thermoplastic, perfect for uses where repeated flexing might wear out a weaker material. LEGO uses this for Dots and VIDIYO straps, but also other semiflexible parts like DUPLO dog ears. TPU is harder and stronger than MTPO.

SEBS (Styrene-Ethylene-Butylene-Styrene)

SEBS is a thermoplastic that behaves like rubber, without needing vulcanization. LEGO uses this for tires — and, famously, LEGO makes most of the tires in the world, by number if not by mass! I believe that LEGO used to make their tires out of styrene-butadiene-styrene (SBS), which is less stable and heat-resistant than SEBS.

PET (Polyethylene Terephthalate)

Image via LEGO

No photo here, sorry. PET, a type of polyester, is a versatile plastic used for water bottles (among a myriad of other items including fabrics and electronics). LEGO currently uses PET for thermoformed clamshell packages such as Build-a-Minifig packages and comic con promos. LEGO has been prototyping actual bricks in this plastic, due to its readily recyclable nature (when not thermoformed), but none have been released publicly just yet.

Other Materials

As any LEGO fan knows, not all parts are plastic. LEGO has used all sorts of metals, fabrics, foams, rubber bands, and even wood to complete their sets, giving play functionality, textures, and motion that plastic alone couldn’t.

The Future of Plastics

That’s all the plastics LEGO has used that I’m aware of — far more than I thought when I started, and I’m certain I haven’t caught all of them! In 2015, LEGO announced plans to invest 1 billion DKK (~$150m USD) in developing new sustainable materials for their products over the following 15 years, kicking off with the 2016 opening of their LEGO Sustainable Materials Centre in Billund. In 2018, the first plant-sourced polyethylene parts started appearing in sets. By 2020, plastic shopping bags were being phased out in LEGO stores. And in late 2020, LEGO announced that they were massively reinforcing their sustainability plan, investing $400m USD to replace all packaging with sustainable materials (as well as other “social responsibility initiatives”). Paper bags are already replacing plastic bags inside sets this year.

So what becomes of ABS, the plastic that accounts for around 80% of LEGO’s production? LEGO has tested “over 250 variations of PET”, as well as hundreds of other plastics — a New Elementary article mentions test bricks made from corn, algae, and wheat! But as of now, no final replacement has been announced, and the vast majority of LEGO parts remain fossil-fuel-based. I look forward to seeing what LEGO comes up with by 2030, and given our present climate crisis, it can’t come soon enough.

A Palatable Postscript

Image via Candy Blox

Just for fun, what are some materials that LEGO hasn’t used for building bricks? We’ve seen wooden bricks from Eco-Bricks and Mokulock, even as early as Halsam’s American Bricks in 1939. Various brands have made a variety of metal bricks as desk toys for adults. Minibrix and Bild-O-Brik, arguably the very first building toys with a stud-and-tube concept, used hard rubber bricks in the mid-1930s.

Hilary Page’s Kiddicraft used urea-formaldehyde along with Bakelite for their toys. I have a 2x4 brick made of corn-based PLA (I wish I knew who made it) — not only bio-sourced but biodegradable too! The company Bio-On has been testing sustainable bricks made from PHA. Batima, a brand from 1930s Belgium, made bricks from Galalith, which comes from casein (milk protein) — not edible, unlike Candy Blox, which are made from compressed dextrose!

Best of BrickNerd - Article originally published May 20, 2022.

Do you know of any other LEGO plastics that we missed? Let us know in the comments below!

Do you want to help BrickNerd continue publishing articles like this one? Become a top patron like Charlie Stephens, Marc & Liz Puleo, Paige Mueller, Rob Klingberg from Brickstuff, John & Joshua Hanlon from Beyond the Brick, Megan Lum, Andy Price, John A., Lukas Kurth from StoneWars, and Wayne Tyler to show your support, get early access, exclusive swag and more.